Zoom out: Industry 4.0 and business consultancy

From strategy to shop floor

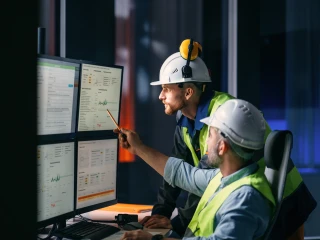

In 2022, delaware established a management consultancy team to guide organizations more effectively towards the most suitable technologies and solutions. "Together with our clients, we develop a strategy for the coming years, with objectives such as process optimization and cost savings,” explains Simon Nuttin, Manager Supply Chain at delaware. “This strategy is then translated into a roadmap with concrete projects. Whether a company aims to save costs, increase production flexibility, or achieve sustainable manufacturing, our team assists in defining and implementing the necessary steps.”

But there’s more. delaware also collaborates closely with production teams to identify and prioritize opportunities. “By leveraging our in-house expertise in Industry 4.0 and SAP, and our network of Industry 4.0 partners, such as ABB, we can quickly assess the feasibility and costs of solutions and subsequently implement them. Our main objective is to be an accelerator for an Industry 4.0 transformation," Simon concludes.

/thumbnail-(3).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=b7789b87-e725-4ea4-b9e3-d274e0c6d52d&v=&focusX=397&focusY=387&c=44140c2ef671d8368e8a6ad93f0de98a1b7b7d4aa971221254290bd639b6dc8c)

/ABB-Robotics-(2).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=187f919b-df44-40ed-94ac-4aa886c0b64e&v=&c=11d4c4659b1db0f3b7d768216a0ef4725bce8fbaf4a900d3aae78d128745483a)

/thumbnail-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=ec1e033b-7e89-42bb-9d48-20807958985a&v=&focusX=423&focusY=387&c=dcd2ff6e3f59b1765b1a2cb81bd5cd94b14f15ec004f71c4c19b892abb95403f)