Taking land-based vehicles into the cloud

Two ongoing delaware projects help illustrate the business value of connected vehicle solutions: AVR’s connected tractor solution and the Gillet connected race car.

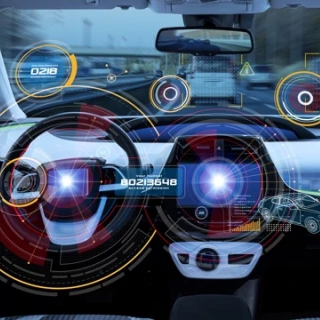

“For both of these projects, delaware made it possible for data and signals generated by CAN bus systems to be uploaded to the cloud, opening up web and mobile applications. The information is then visualized via an intuitive online dashboard,” explains Bruno.

“In the case of AVR, an MS Azure-based platform, the information generated by these connected tractors is used in crop and agricultural field management, ultimately aiming to provide continuous cultivation advice to the farmer. With Gillet, a Belgian motorsports company, the goal is quite different. While the performance of their connected race car, the Vertigo, can be tuned using track data, the data can also be displayed in real time for the benefit of the audience – features that are sure to give Gillet an edge during the upcoming race at Pikes Peak.”

/Top-story_2-Website-720x360-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=a3342c21-9c5c-4be1-a522-329c63a9ebe6&v=&focusX=444&focusY=157&c=6aff166a2f7f7c2f5970e4023c0807b87a40c8c1715ef07f4d68d855ee2090cd)

/Agoria_Solar_team-Website-720x360-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=076eb515-2fdb-4ce7-abfe-8f4861ccf2fd&v=&focusX=435&focusY=169&c=3d1243fe2c4bdb33aef13f55b99212abcf8243a33a6bca8fad63b6dbe0182d36)

/Topstory2-CIO-June2020-Website-720x360-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=6eedca38-36ff-41eb-bb64-c823818fda2a&v=&focusX=438&focusY=197&c=5c8fe6dba53df930f9daa367db9b90180caddda5590fe3c13dbe04b2c787c173)

/Topstory1-CIO-June2020-Website-720x360-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=a1fe907a-a4f3-4143-a719-82e5404f284f&v=&focusX=422&focusY=139&c=8921b13e43baf32a4b2ab86cce00eb8bfd1b94b6a23b8989b5c2843a62bce382)