More than Material: The New Era of Plastics Processing

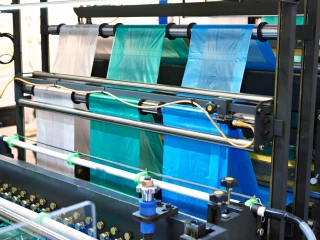

The plastics processing industry is undergoing profound transformation. Rising material and energy costs, a shortage of skilled labor, and growing demand for environmentally friendly products manufactured through sustainable processes all require new solutions.

Companies are responding with more efficient methods, innovative materials, and a clear focus on recyclability. Those who invest today in modern technologies and sustainable processes will secure tomorrow’s competitiveness.

/AdobeStock_423962098-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=68d209c2-04ed-4194-9ba5-bdf2f8865f9c&v=&c=67806f2f8cf64be7f98dbbc0048b2fea1ff8be914a05ac46cc64a43b1dbbf39b)