Optimising Order Fulfillment and Supply Planning: The Role of S&OE and SAP IBP

In our daily operations, we deal with various types of orders: sales, purchase, and production/process orders. Sales and Operations Execution (S&OE) helps to drive order fulfillment and logistical execution.

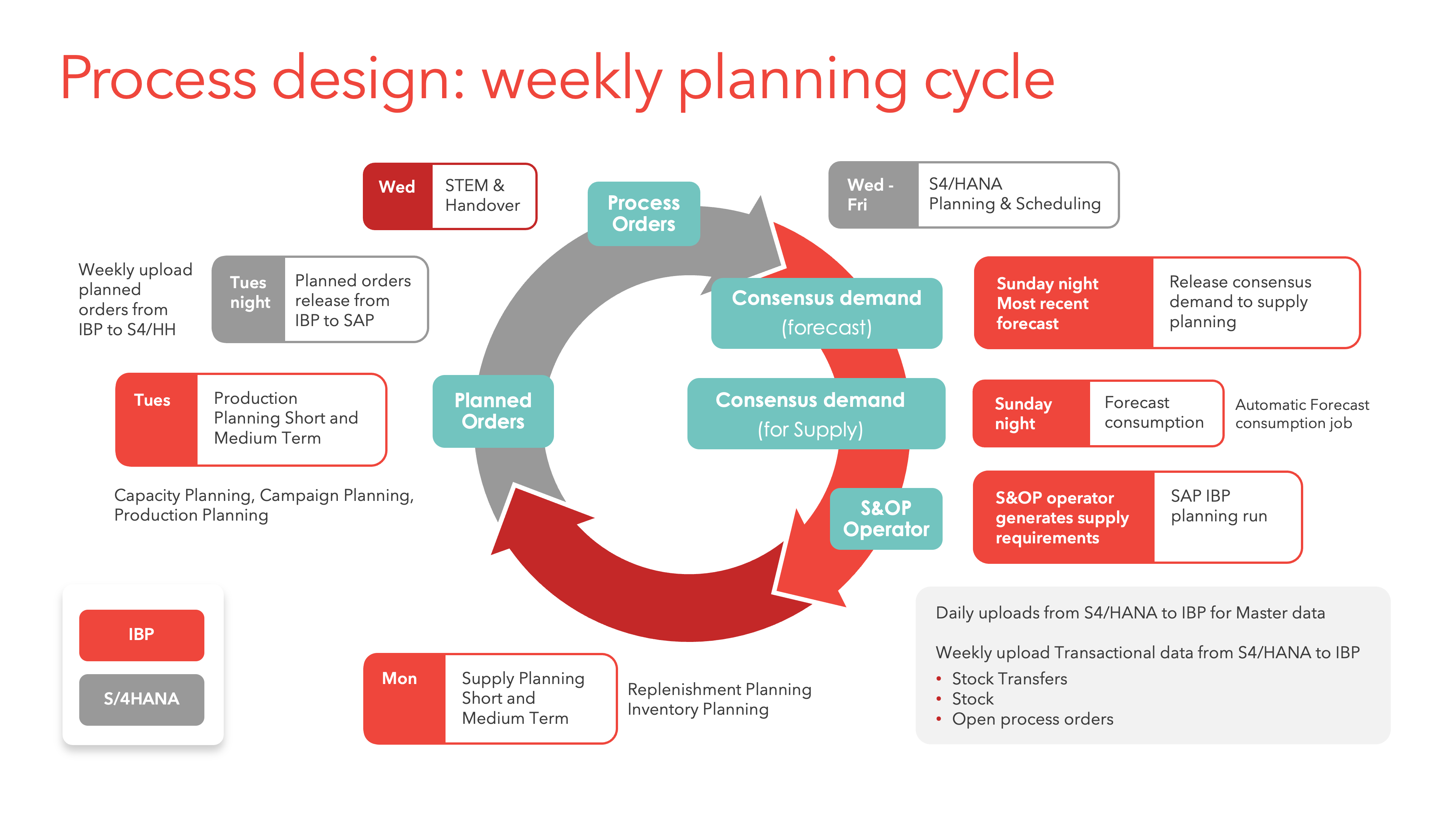

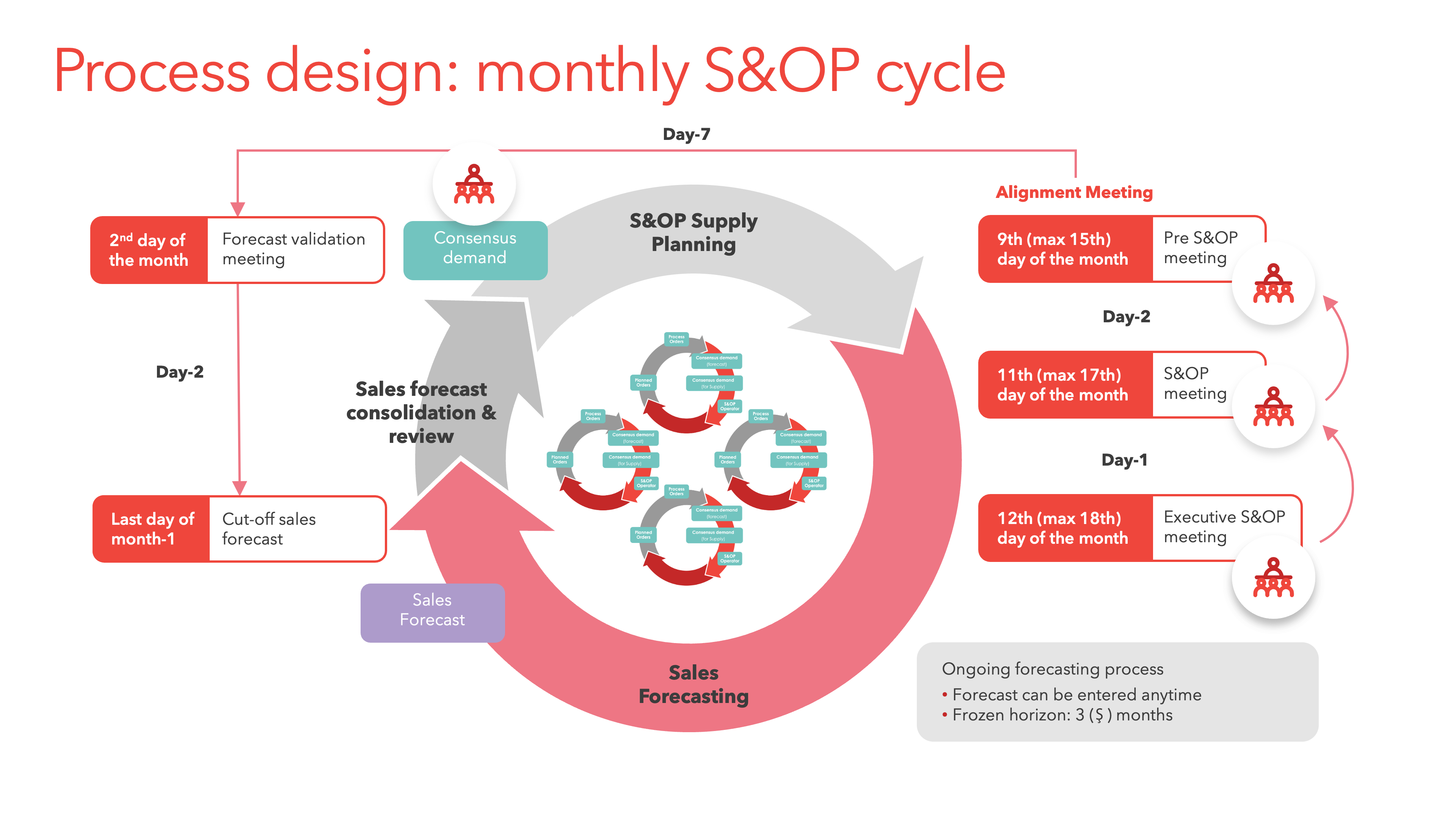

During our S&OP processes, we look at data differently. We analyse data at aggregated levels like product groups, customer segments, and regional or global scales, rather than examining individual orders. After S&OP, the planning cycle continues, with consensus demand integrated into operational processes.

For organisations with a regional or global presence and complex supply networks involving warehouses or 3PLs, it's advisable to integrate 'IBP planned orders' for enhanced supply planning, including network and stock management.

IBP, while not a scheduling tool (SAP S/4HANA ePPDS is recommended for scheduling), is valuable in S&OP for consolidating network demand, conducting time series-based capacity and raw material planning, and utilising S&OP operators (heuristic and optimizer) to optimize the supply plan. Additionally, IBP supports the use of time series planning wheels and campaign plans for proactive supply planning.

.png)